We support CNC machining projects through a qualified manufacturing partner network, covering prototype development, batch production, and sustained high-volume programs. Our role focuses on engineering communication, manufacturability review, and production coordination to ensure stable quality and delivery at scale.

Supported Industries

Our CNC machining capabilities support a wide range of industrial and technical applications, including but not limited to:

Industrial equipment & machinery components

Automation & robotics parts

Medical devices (non-implant components)

Electrical & electronic hardware

Automotive components & assemblies

Energy, power, and infrastructure equipment

Consumer and commercial hardware products

Projects with defined drawings, tolerance requirements, and production intent are best suited for our workflow.

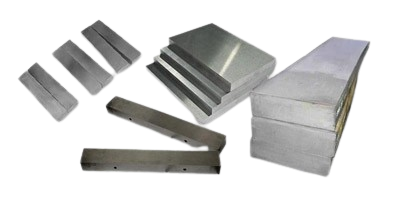

Steel & Alloy Steel

AISI 1020, AISI 4140, AISI 440C, 12L14,

C45 (EN)

Tool steels and equivalent grades available upon request

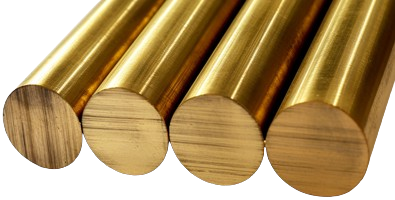

Copper Alloys

Brass, Bronze, Tin bronze, Beryllium copper

Equivalent grades available upon request

Precision CNC Machining

Materials Capability

We support machining of common aerospace, industrial and medical-grade alloys. Material selection can be tailored based on mechanical properties, environmental requirements, and project specifications.

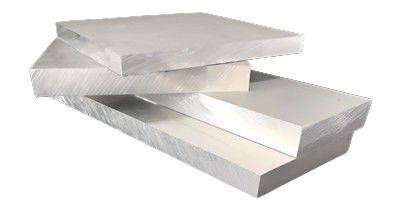

Aluminum Alloy

6061-T6, 7075-T6, 2024-T351, 5083, 5052, 5056, 6063, 6082,

Equivalent grades available upon request.

Engineering Plastics

PEEK、POM、ABS、PC、PA66、PMMA、PTFE etc.

Surfacing Treatment

Available surface treatments and finishes include:

Anodizing

Hard anodizing

Black oxide

Powder coating

Electropolishing

Plating and custom finishes upon request

Finishing processes are selected based on functional, cosmetic, and environmental requirements.

Production Scale Support

Tolerance & Precision

Standard machining tolerance: ±0.01 mm

Tighter tolerances available upon engineering review

Critical dimensions evaluated during DFM and process planning

Inspection & Quality Support

Dimensional inspection

First Article Inspection (FAI)

CMM measurement support

In-process and final inspection

Traceability available for selected production programs

RFQ Guidance

Our manufacturing partners are capable of supporting scalable production programs, including:

Prototype & pilot runs

Batch production

High-volume repeat orders

Long-term production programs

We assist clients in transitioning from initial validation to stable volume production while maintaining consistent process control and quality monitoring.

For efficient quotation and engineering review, please prepare:

2D drawings and/or 3D models

Material specification

Tolerance requirements

Target quantity and production intent

Application context (industrial, medical, automation, etc.)

How We Work

Lenora Solutions operates as an independent sourcing and integration partner.

We do not promote a single factory or brand, instead, we coordinate qualified manufacturing resources based on project requirements, production scale, and compliance needs.

Our approach is designed to reduce supplier switching as projects scale from development to volume production.

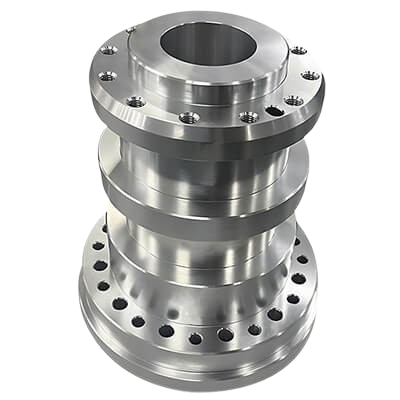

CNC Machining Processes We Support

We support a full range of CNC machining processes through our manufacturing partners:

CNC Milling (3-axis / 4-axis / 5-axis)

CNC Turning

Mill-turn combined parts

Complex contour and multi-face machining

Prototype, pilot, and production machining

Stainless Steel

303, 304, 316L, 17-4PH

Equivalent grades available upon request.

Titanium Alloy

Grade 2, Grade 5 (Ti-6Al-4V)

Equivalent grades available upon request